Products

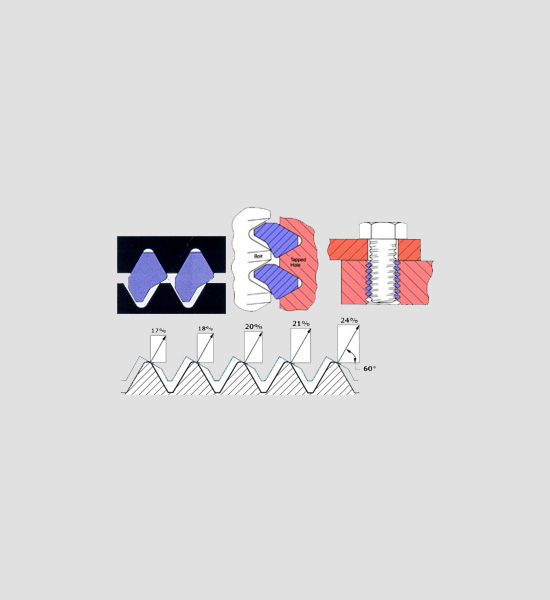

inserts are precision formed screw thread coils of

stainless steel wire having a diamond shape cross section.

Heli-Coil precision formed wire inserts are readily

recognized and highly regarded products in the industry.

Since its inception in 1938, Heli-Coil has been identified

as an industry leader offering products with superior

performance, reliability and integrity.

Helicoil inserts are used into softer metallic or non

metallic materials to give them steel-like thread

performance. This has enabled industries to use lighter

weight materials such as aluminum, FRP, Nylon etc without

having to give up thread strength of their fasteners.

Heli-Coil strict quality programs ensure to meet the

latest industry standards of QS,ISO,TS and AS

specifications, as is evident in Heli-Coil track record of

consistently passing audits without technical findings.

Heli-Coil SPC and detailed inspection programs elevate the

quality levels well above our competitors. Heli-Coil wire

inserts and related assembly tools are manufactured with

over 65 years of experience. Heli-Coil teams are dedicated

to exceeding customer's expectations by providing

innovative value added design and engineering services,

on-time deliveries and excellent customer service support.

Heli-Coil is committed to developing superior products

manufactured to only the highest quality standards. We are

more than just a supplier, we are a business partner.

Heli-Coil in USA is manufactured by Stanley Engineered

Fastening

Heli-Coil Tangless Inserts eliminate tang break-off and

retrieval and are easily adjusted or removed after

installation. The Bi-Directional Design installs quickly

and easily from either end of the insert. HELI-COIL

Tangless inserts have a bi-directional design allowing the

insert to be installed from either end Tangless inserts

are available as free running & screw locking Types, with

all regular coatings.

Heli-Coil Tangless screw lock inserts provide a positive,

self-locking torque and comply with both MIL-I-8846

/NASM8846 and NAS1130 requirements.

Typical Tangless NAS1130 Parts can be identified as in the

product line card available at this site.

With tangless® inserts, no loose tangs are left behind,

and they are the solution when foreign object debris (FOD)

cannot be present in critical applications. They eliminate

the need for tang break-off and tang retrieval and can be

easily adjusted or removed after installation.

Tangless threaded inserts provide permanent,

wear-resistant screw threads that completely eliminate the

need for tang break-off and retrieval.

The "Screw-Locking" tangless®insert provides self-locking

torque on the male member by a series of "chords" on one

or more of the insert coils.

With tangless inserts, no loose tangs are left behind, and

they are the solution when foreign object debris (FOD)

cannot be present in critical applications. They eliminate

the need for tang break-off and tang retrieval and can be

easily adjusted or removed after installation.

Helicoil Nitronic 60 Inserts are available in Tanged and

Tangless both versions.

Helicoil Nitronic 60 Inserts are available in Free Running

type and Screw Locking Type.

Helicoil Nitronic 60 Inserts are Superb gall resistance

Helicoil Nitronic 60 Inserts are Compatible with stainless

steel screws

Helicoil Nitronic 60 Inserts are Ideal for use in vacuum

environments

Helicoil Nitronic 60 Inserts Requires no additional

coatings or plating

Helicoil Nitronic 60 Inserts are Particle free and

Non-magnetic

Helicoil Nitronic 60 Inserts are made with Material Spec:

UNS S21800 Can withstand Temperature range: up to 500°F

having Tensile strength of 200,000 PSI And Hardness of RHc

43-50

Helicoil Nitronic 60 Inserts are Moderate Corrosion

resistance and having Magnetic Permeability of <1 G/o

Helicoil DFL Coated Inserts are available in Tanged and

Tangless both versions.

Helicoil DFL Inserts are available in Free Running type

and Screw Locking Type.

Helicoil DFL Inserts Provides additional lubrication in

high friction applications And High temperature resistance

(400°F)

Helicoil DFL Inserts are Highly recommended with Heli-Coil

Screw-Locking inserts

Helicoil DFL Inserts Mildly corrosion resistant

Helicoil DFL Inserts coating Material Spec is AS5272 and

is Gray in colour.

Helicoil Cadmium Plated Inserts are available in Tanged

and Tangless both versions.

Helicoil Cadmium Plated Inserts are available in Free

Running type and Screw Locking Type.

Helicoil Cadmium Plated Inserts are used For Military

specification purposes only

Not recommended for new design due to its toxic nature

Cadmium Plating Material Spec: QQ-P-416 Type II

Color: Iridescent yellow - Free-Running

Color: Olive drab - Screw-Locking

Helicoil Silver Plated Inserts are available in Tanged and

Tangless both versions.

Helicoil Silver Plated Inserts are available in Free

Running type and Screw Locking Type.

Helicoil Silver Plated Inserts are Recommended to reduce

galling of threads at high temperatures

For use up to 1200°F

Silver Plating » Highly recommended with inserts made from

Inconel X-750

Material Spec: QQ-S-365

Color: Silver white

Helicoil Primer-Free tangles inserts are designed for use

in applications where galvanic corrosion between

dissimilar metals is a concern. Coating not only protects

the base material and provides excellent lubricity, but

more importantly, eliminates the need for liquid chromate

primers. With Primer-Free coated inserts, the inserts are

always evenly coated, providing more accurate bolt

torques.

Spiralock inserts are made of cold-rolled Type 304

stainless steel wire (AS7245), work-hardened to a tensile

strength above 200,000 psi, having a hardness of Rc43-50.

The finished surface (8-16 micro inches) is exceedingly

smooth, virtually eliminating friction-induced thread

erosion.

It is important to select the proper insert length in

order to balance the bolt tensile strength against the

shear strength of the parent material. The insert lengths

are calculated numbers because the inserts cannot be

measured in the free state. The lengths are multiples of

the nominal thread size, or diameter, of the insert.

Please see Table III for insert dimensions. Using the

insert length selection table below, an insert length can

be selected which will produce a thread system strong

enough to fracture a bolt before it will strip or damage

either the parent material or the insert.

Spiralock wire thread inserts are helically coiled

fastening devices that provide permanent, wear-resistant

screw threads that exceed the strength of most parent

material; the inserts are designed to protect tapped holes

against failures due to stripping, seizing, corrosion, and

wear. Spiralock inserts are unlike any other wire thread

insert due to the fact that our inner diameter wire

geometry incorporates our 30° wedge ramp thread form

design. Our wire thread inserts are available in two

styles: tanged and Drive Notch, engineered with no

tang.

Crest of bolt seats against ramp of Spiralock insert

thread profile, preventing transverse movement of bolt

relative to insert, thus resisting loosening due to

vibration. Spiralock insert meets or exceeds the

applicable parts of NASM8846; e.g., the wire tensile

strength, chemical composition, and methods of

inspection.

Spiralock insert is not a prevailing torque-type

screw-locking insert—no risk of galling or seizing of bolt

and insert Similar to NASM1130 inserts Provides proven

superior vibration resistance to standard locking

inserts.

Spiralock wire thread inserts are helically coiled

fastening devices that provide permanent, wear-resistant

screw threads that exceed the strength of most parent

material; the inserts are designed to protect tapped holes

against failures due to stripping, seizing, corrosion, and

wear. Spiralock® inserts are unlike any other wire thread

insert for the fact that our inner diameter wire geometry

incorporates our 30° wedge ramp thread form design. Our

wire thread inserts are available in two styles: tanged

and Drive Notch, engineered with no tang.

Crest of bolt seats against ramp of Spiralock insert

thread profile, preventing transverse movement of bolt

relative to insert, thus resisting loosening due to

vibration.

HeliCoil Tangless HEX Electrical Insertion Tools are used

with Helicoil Power Tools such as Helicoil Electrical

Power Drivers, Helicoil Battery Operated Power Drivers and

Helicoil Pneumatic Power Tools. Helicoil Hex Installtion

Tools are Easy and faster to use, Quick Changing,

Available in sizes from M2 to M24 and equivalent Inch

Sizes. Depth Stopper ensure perfect installation of insert

till required depth. External HEX is as per DIN 3126/ ISO

1173

HeliCoil Tangless Insertion Tools - Prewinder Type are

available from size M2 – M12 and in UNC / UNF category

from 1-64 to 1/2". HeliCoil Tangless insertion tools are

best suited for easy & fatigue free installation of

inserts in production line to achieve a high quality of

HeliCoil insert installation & prevent jumping of coil

threads. Threaded mandrel prewinders are also best

recommended for successful installation of screw locking

inserts and free running inserts having a fine thread

pitch.

HeliCoil Tangless Insertion Tools - Guage Type are

available from size M2 – M12 and in UNC / UNF category

from 1-64 to 1/2". HeliCoil Tangless insertion tools Gauge

type are quick and easy to us. They are best suited for

easy & fatigue free installation of inserts in production

line to achieve a high quality of HeliCoil insert

installation & prevent jumping of coil threads.

HeliCoil Tangless Insert Removal Tools - Guage Type are

available from size M2 – M12 and in UNC / UNF category

from 1-64 to 1/2".

Helicoil Tangless Removal Tool is unique in the helical

coil screw thread insert industry. The Helicoil Tangless

removal tool allows quick, non-destructive removal of

Tangless inserts, preventing damage to the parent material

and expensive castings.

The Helicoil Tangless removal tool simply threads into the

installed insert, grabs the removal notch and threads the

insert out without damaging the internal STI threads or

surface of the casting. Helicoil Tangless removal tool has

ability to back out or adjust an insert that has been

installed too deep; giving operators greater control over

installation depth.

HeliCoil Threading Taps are available in HSS material as

standard product and as specials in HSSE or HSS with High

Cobalt contents. In addition the taps can also be provided

with special wear resistant coatings.

Standard HeliCoil taps are designed and manufactured of

high speed steel to the most rigid specifications in

various types and styles to produce holes for tolerance

class 4H5H and 5H6H in Metric series and of class 2B/3B in

UNC/UNF series for use in the general range of aluminums,

magnesiums, mild steels and alloy steels.

Types of HeliCoil taps:

HeliCoil Gauges are available as Go/No Go thread plug

gauges for inspection of tapped holes prior to HeliCoil

fitment. The gauges are available in 5H & 6H class for

Metric sizes and 2B/3B for UNC/UNF sizes.

Accuracy of the finished thread when the insert is

installed is dependent upon the accuracy of the tapped

hole. If the finished tapped hole gages satisfactorily,

the installed insert will be within the thread tolerance.

It is not necessary to gage the installed insert. After

the insert is installed, the GO thread plug gage may not

enter freely; however, the insert will always seat itself

when the bolt or screw is installed and tightened.

(Reference NASM33537).

Gage handles and all gage nibs are marked with the extreme

product limits for the particular size and class of fit.

When gaging tapped holes which have been thoroughly

cleaned or which have a protective finish applied, the

gage should always be lubricated with light oil. HI nib

may enter provided a definite drag results on or before

3rd turn from entry – Ref. FEDSTD-H28, Screw thread

Standards for Federal Services.

Working gages provide a guaranteed minimum wear allowance

on the pitch diameter of the GO members of two ten

thousandths of an inch (.0002). These gages are

recommended for production in sizes 1/2 inch and

smaller.

Reference gages have pitch diameters on or close to

minimum (basic size). They are essentially laboratory or

master gages and should be used in case of conflict

between two working gages. Conflict can occur when one of

the gages has experienced more use and wear.

The complete gage consists of the GO thread plug gage, the

HI thread plug gage and the appropriately marked gage

handle. Accuracy of the finished thread, when the insert

is installed, is dependent upon the accuracy of the tapped

hole.

Heli-Coil power tools are available in Inch and Metric

sizes #2 (M2.2) thru 1/2"* (M12) for rapid installation of

Heli-Coil inserts. Power tools consist of a Front End

Assembly, an Adapter and a reversible Air Motor. All three

components are ordered separately.

A Front End Assembly consists of a prewinder, mandrel and

spacers. Select the adapter that corresponds with the

insert size being used. Power tools for strip feed inserts

are available in sizes #2 (M2.2) through 5/16" (M6).

Heli-Coil metric power inserting tools are available in

coarse and fine sizes up to 12mm* for rapid installation

of standard and screwlock inserts, substantially reducing

assembly costs. Strip feed power tools are available in

sizes up to 7mm. They speed up assembly, eliminate waste

and permit an accurate count.

Power tools consist of a Front End Assembly, an Adapter

and a reversible Air Motor. All three components are

ordered individually. A front end assembly consists of a

prewinder, mandrel and spacers. Select an Adapter that is

compatible with the insert size to be used, and for the

size range up thru 6mm or the size range 7mm thru 12mm.

Pneumatic Power Tool Installation Kit

This Heli-Coil power tool installation kit (8522) contains

an Air Motor (8510-1), adapter, tools, a

filter-regulator-lubricator, oil, two quick disconnect

fittings, and wrenches. All are packed in a portable

molded box with easy-to-follow operating instructions.

Front End Assemblies may be ordered separately to fit the

sizes of Heli-Coil inserts to be installed.

Heli-Coil offers an electronic power tool where electric power is preferred over air. The slender configuration of the mandrels allows them to reach into constricted areas. Electric power meets the requirements of clean room operations. Operators prefer electric power because it is quieter. The electronic tool is lighter to minimize operator fatigue. Mandrel assemblies are available to install the sizes of Heli-Coil inserts listed in the chart. Application Note: Variations in Mandrel Assembly dimensions and threads are available on a special order basis. Please contact Heli-Coil Applications Engineering Department at 0091 9901522733 to discuss your application.

Heli-Coil offers an electronic power tool where electric power is preferred over air. The slender configuration of the mandrels allows them to reach into constricted areas. Electric power meets the requirements of clean room operations. Operators prefer electric power because it is quieter. The electronic tool is lighter to minimize operator fatigue. Mandrel assemblies are available to install the sizes of Heli-Coil inserts listed in the chart. Application Note: Variations in Mandrel Assembly dimensions and threads are available on a special order basis. are available on a special order basis. Please contact Heli-Coil Applications Engineering Department at 0091 9901522733 to discuss your application.

The re-designed Heli-Coil power tool holder utilizes a

strong tubular design to decrease weight and increase

rigidity and tool support. The new unit now features a

solid base that can be bolted to the work surface to

maintain perpendicularity between the tool and the work

piece. Because of this, the tool holder is especially

recommended for use with small thread sizes (#2-56, M2.2,

M2.5) and is ideal for use in applications with inserts to

be installed within the same plane.

Additional features include a filter-regulator-lubricator

mount and insert reel mounting arm. The tool can be

quickly and easily converted for use with either the

traditional air operated installation tool or the

Heli-Coil Electronic Installation System.

Features & Benefits

The re-designed Heli-Coil power tool holder utilizes a

strong tubular design to decrease weight and increase

rigidity and tool support. The new unit now features a

solid base that can be bolted to the work surface to

maintain perpendicularity between the tool and the work

piece. Because of this, the tool holder is especially

recommended for use with small thread sizes (#2-56, M2.2,

M2.5) and is ideal for use in applications with inserts to

be installed within the same plane.

Additional features include a filter-regulator-lubricator

mount and insert reel mounting arm. The tool can be

quickly and easily converted for use with either the

traditional air operated installation tool or the

Heli-Coil Electronic Installation System.

Features & Benefits

Heli-Coil inserts and tooling comply with the following standards and Specifications: